Product Features

- High density filter cake

- Adjustable filter cake density and filtration concentration

- Compared with liquid capacity, small space required

- Best results in filter cakes

Technical Drawing

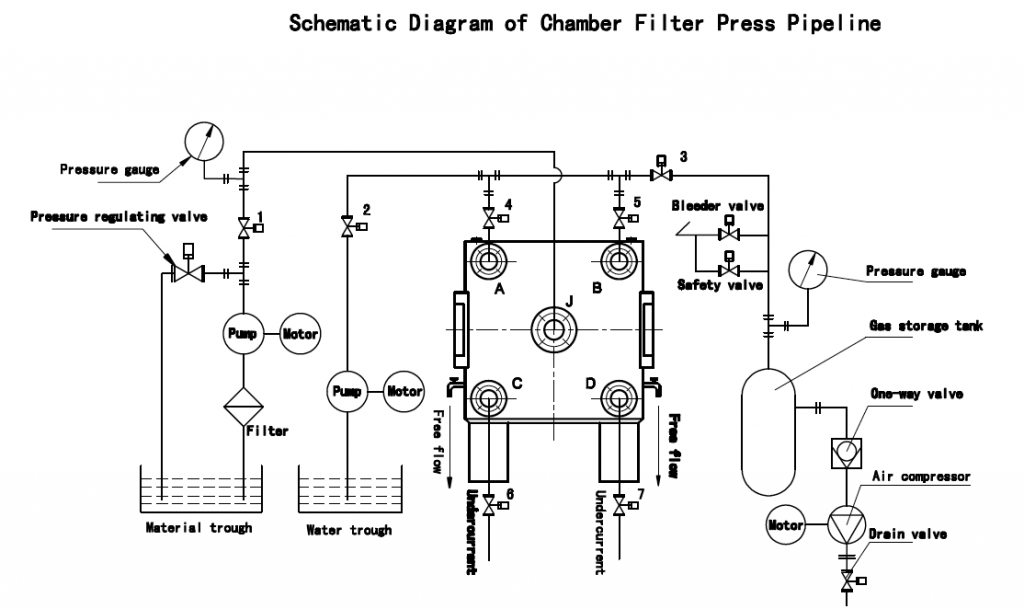

Operation Illustrations

- Non-Washable External Output Models: Seal A, B, C, D, use non-wash cycle. Open 1 to allow raw materials into the chamber, adjust volume and pressure to allow optimal liquid output. When compressing, close 1, open 3, F to allow compressed air in for processing. After process completes, open drain valve to let out filtered air.

- Washable External Output Models: Seal C, D, open 1 to allow raw materials into the chamber, adjust volume and pressure to allow optimal liquid output. When compressing, close 1, open 3, F to allow compressed air in for processing. After process completes, open drain valve to let out filtered liquid. When using wash cycle, close 1, turn off facets on washboard, open 2, 4, 5, A, B to allow water through for processing.

- Non-Washable Internal Output Models: Seal A, B, no liquid output, open 1 to allow raw materials into the chamber, liquids flow out through 6, 7. When compressing, close 1, open 3, F allows compressed air for processing. After process completes, open drain valve to let out filtered liquids.

- Washable Internal Output Models: Seal 4, 5, open 1 to allow raw materials into the chamber, open 6, 7, to allow liquids flow through. When compressing, close 1, open 3, F allows compressed air for processing. After process completes, open drain valve to let out filtered liquids. If cross wash cycle is needed, first open 2, 4, 7, then close 1, 5, 6, water input through A, C onto washboard, output through B, D. Then close 1, 4, 7, open 2, 5, 6, water input through B, D, output through A, C.

Note

- Washable system and cleaning system can be selected according to the user process conditions

- Each valve should be installed as close as possible to thrust plate as well as reduce curves

- Press media type: water, oil, air, etc.

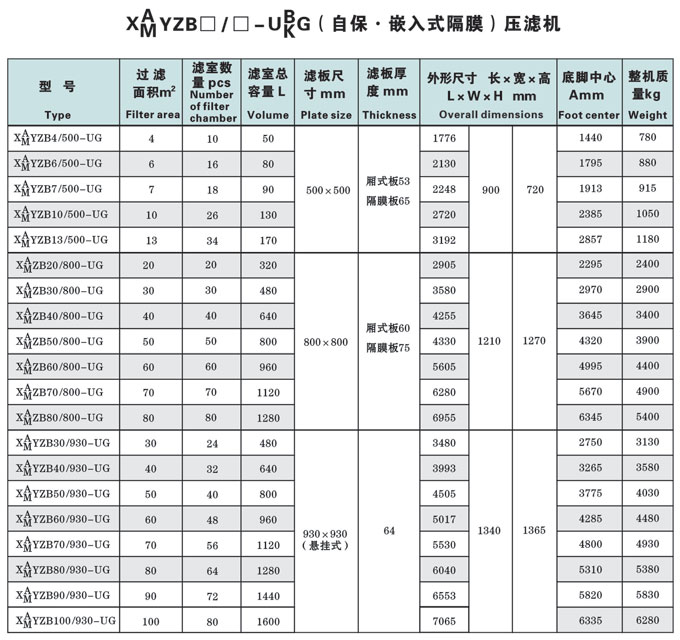

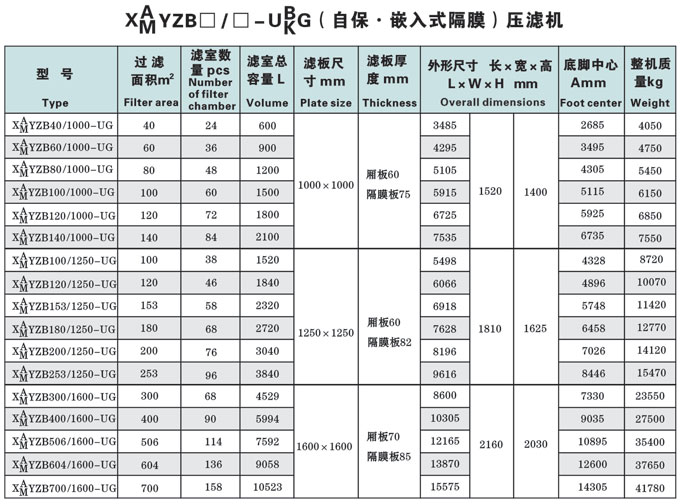

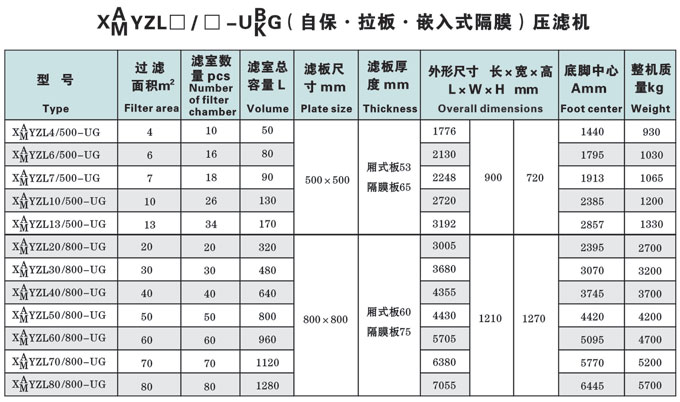

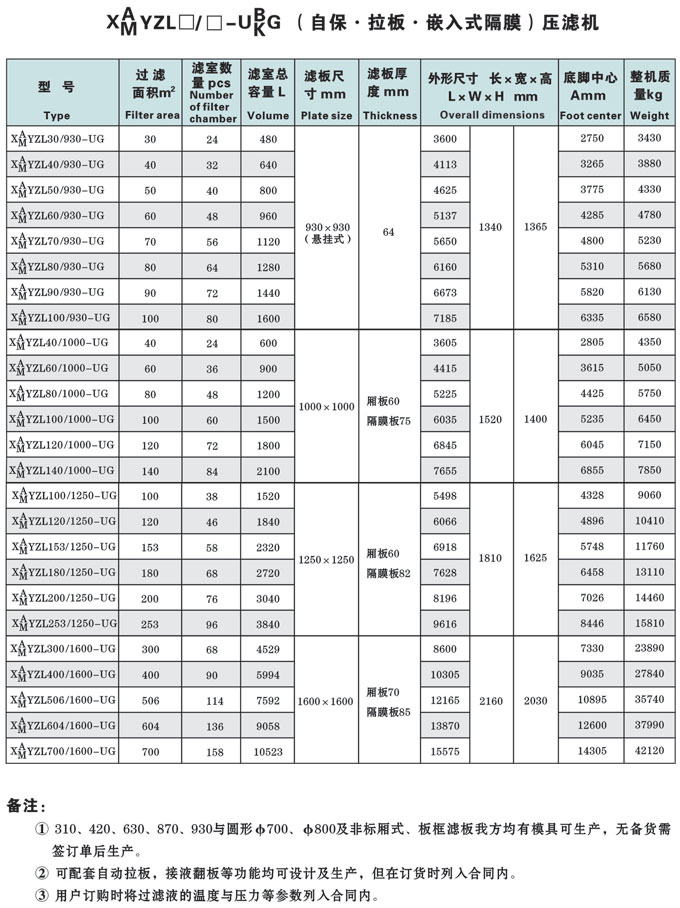

Filter Press Technical Parameters