PP Membrane Filter Press Technical Features

- PP Membrane Filter Plate is made through mold pressing with polypropylene and the import elastomer. It is high in strength, light in weight, corrosion resistant, non-poisonous and no smell.

- Improve filter cake solid content, high in strength of filter cake, easy in discharging cake.

- Membrane squeezing technology, the cracks in the filter cake can be compacted. The washing time is short and effective, less use of washing water.

- Use feed pressure of 0.6Mpa (87.02 psi) -1.6Mpa (232.06 psi). 0.6Mpa (87.02 psi) -2.5Mpa (362.59 psi) squeezing pressure of the filter pressure to ensure the best conditions for the formation of filter cake and pressure filtration.

- PP membrane filter press can also be configured automatically pull board system which only operate control buttons on the control cabinet can be automated. This greatly reduce the work intensity and improve efficiency.

- May dehydrate directly moisture 95% above sludge (such as industrial sludge, city and town sewage, etc.) disposable to 55%-38% levels. It has made revolutionary breakthrough of sludge machinery dehydration technology.

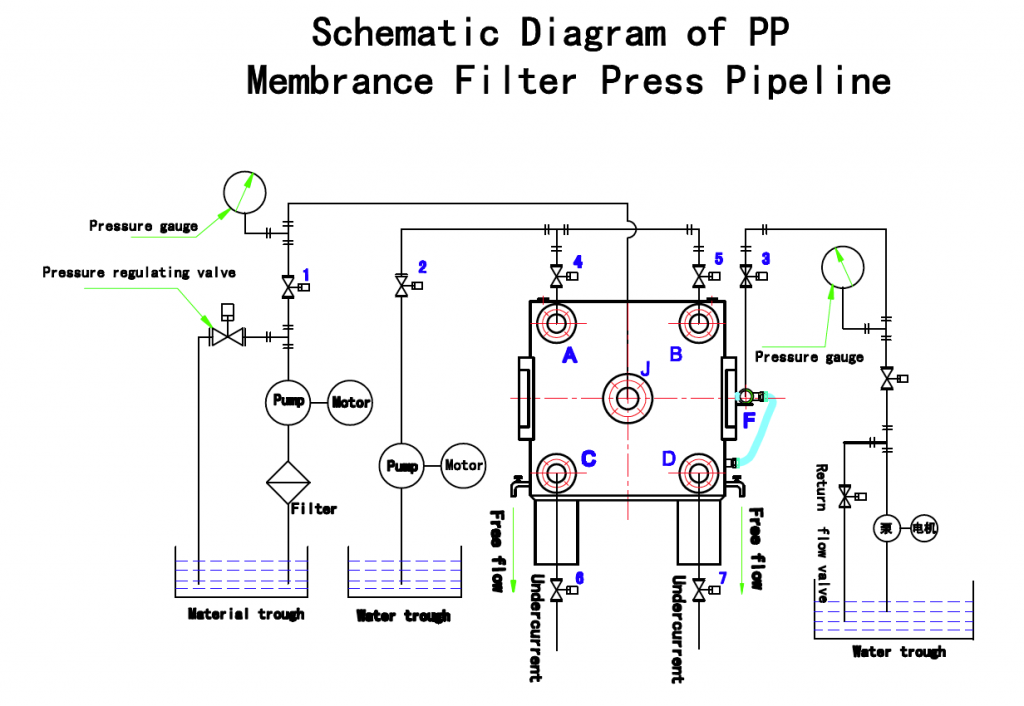

PP Membrane Filter Press Technical Drawing (Click Here to view demo)

Operation Illustration

- Non-Washable Liquid Output Models: Seal A, B, C, D, open 1 to allow raw materials into the chamber, adjust volume and pressure to allow optimal liquid output flow. To compress raw materials, close 1, open 3, water flows through F for processing. Open “Return” valve to let out filtered liquid.

- Washable Liquid Output Models: Seal C, D first, open 1 to allow raw materials into the chamber, adjust volume and pressure to allow optimal liquid output flow. To compress raw materials, close 1, open 3, water flows through F for processing. After the process completes, open”Return” valve to let out filtered liquid. When using wash cycle, close 1, close faucets, open 2, 4, 5, A, B to operate wash cycle.

- Non-Washable No-Liquid Output Models: Seal A, B, turn off faucets. Open 1 to allow raw materials into the chamber, liquid output through 6, 7. To compress raw materials, close 1, open 3, F to allow water through for processing. After process completes, open”Return” valve to allow liquid output.

- Washable No-Liquid Output Models: Seal 4, 5, open 1 to allow raw materials into the chamber, open 6, 7 to allow liquid output. To compress, close 1, open 3, F to allow water through for processing. After process completes, open”Return” valve, let out filtered liquid. When using cross wash cycle, open 2, 4, 7, close 1, 5, 6, water input through A, C into wash cycle, output through B, D. Close 1, 4, 7, open 2, 5, 6, water input through B, D, output through A, C.

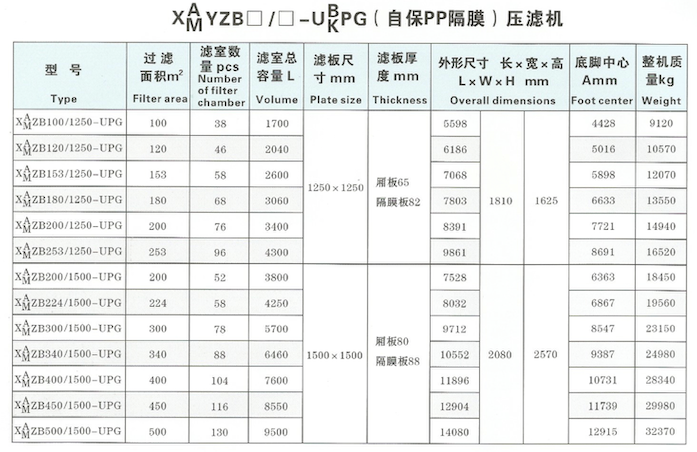

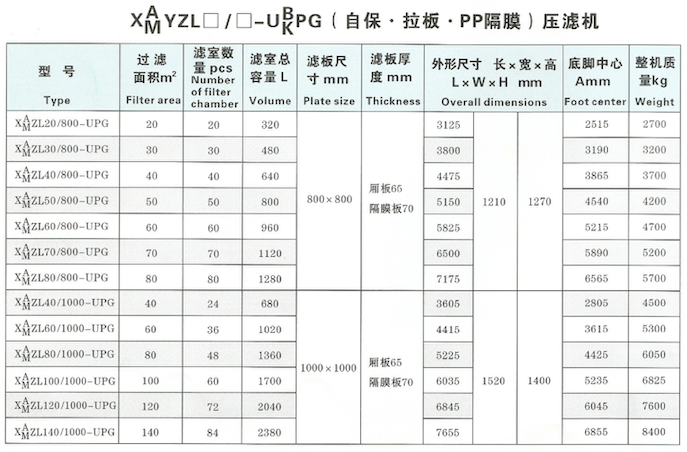

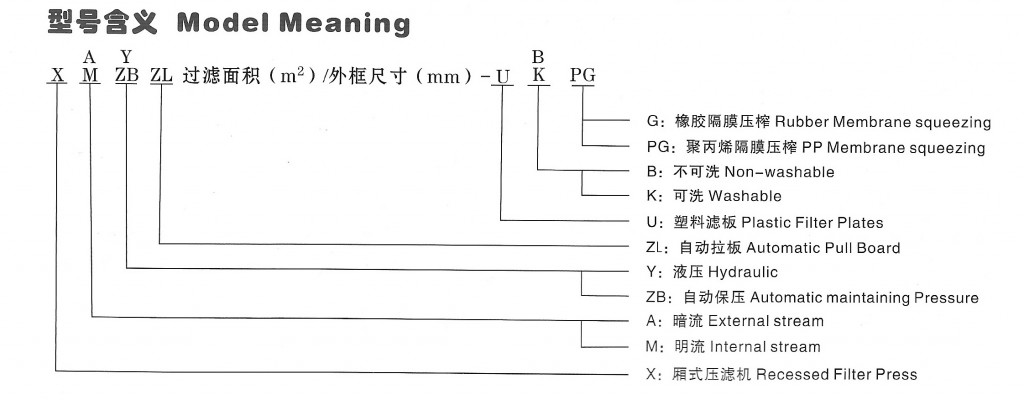

PP Membrane Filter Press Technical Spec

Note:1. 310, 420, 630, 870, 930 and round 700, 800 as well as custom designed filter press and filter press are all built based on project technical specifications.2. Automatic filter plate operations could be added for project needs.3. Please specify filtration temperature and filtration pressure when ordering.