General Recessed Filter Press Technical Features:

- Reinforced polypropylene filter plate using glass fiber reinforced polypropylene repression, high strength, light weight, increasing just toughness, corrosion resistance, high temperature, non-toxic, no smell.

- Using hydraulic pressure, the maximum clamping pressure 25Mpa (3625.94psi), and electrical contact points automatically maintain pressure gauge.

- Maximum filtration pressure up to 1.0Mpa (145.04psi), to ensure the best conditions for the formation of a filter cake, pressurized filtration.

- Simple operation, easy maintenance, and is equipped with multiple safety devices to ensure operator safety.

General Recessed Filter Press Technical Drawings

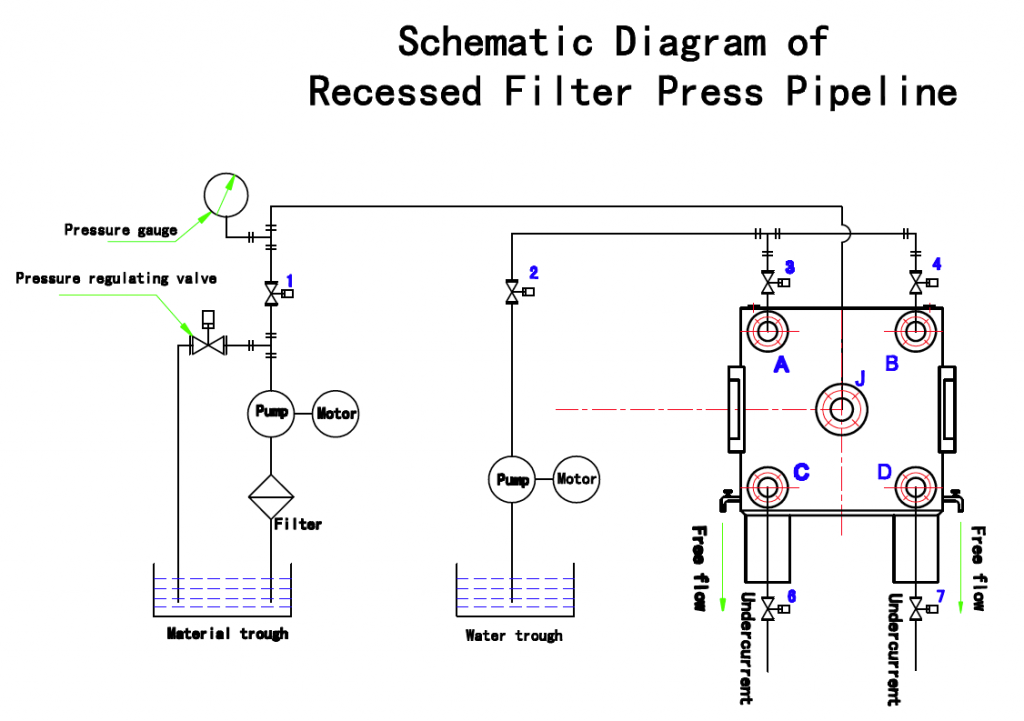

Operations Illustration

- Non-Washable External Stream Models: Seal A, B, C, D, non-wash cycle. Open 1 to allow raw materials into the chamber, adjust volume and pressure for optimal output. Liquid output through “Free Flow” faucets.

- Washable External Stream Models: Seal C, D, open 1 to allow raw materials into the chamber, adjust volume and pressure for optimal performance, turn on faucets to allow liquid output. When using wash cycle, close 1, turn off faucets on washboards, open 2, 3, 4, A, B to input wash liquids for wash cycle.

- Non-Washable Internal Stream Models: Seal A, B, no “Free Flow” faucets. Open 1 to allow raw materials into the chamber, output through 6, 7.

- Washable Internal Stream Models: No faucets for liquid output. Seal 3, 4, open 1 to allow raw materials input, open 6, 7 for liquid output. When using cross wash cycle, first open 2, 3, 7, close 1,4,6. Wash liquid input through A, C, output B, D. Then, close 1, 3, 7, open 2, 4, 6, wash liquid input B, D, output A, C.

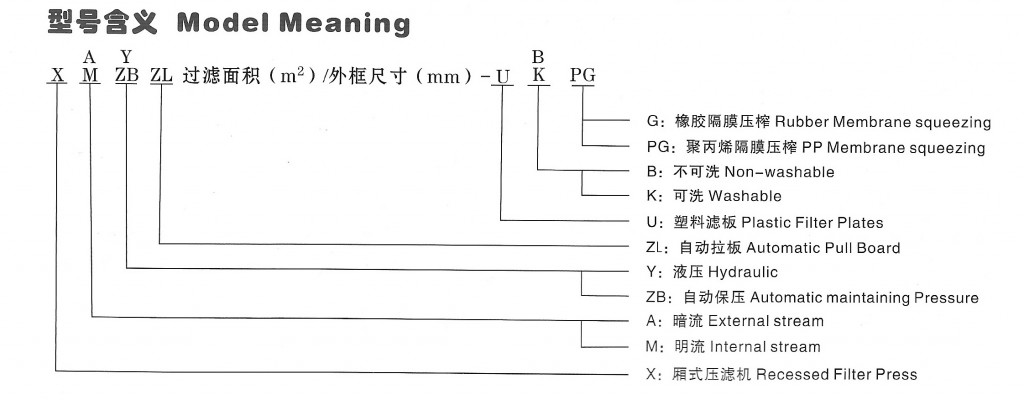

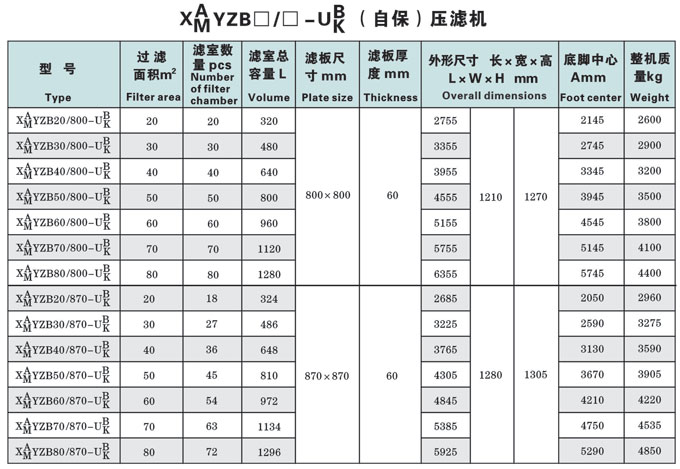

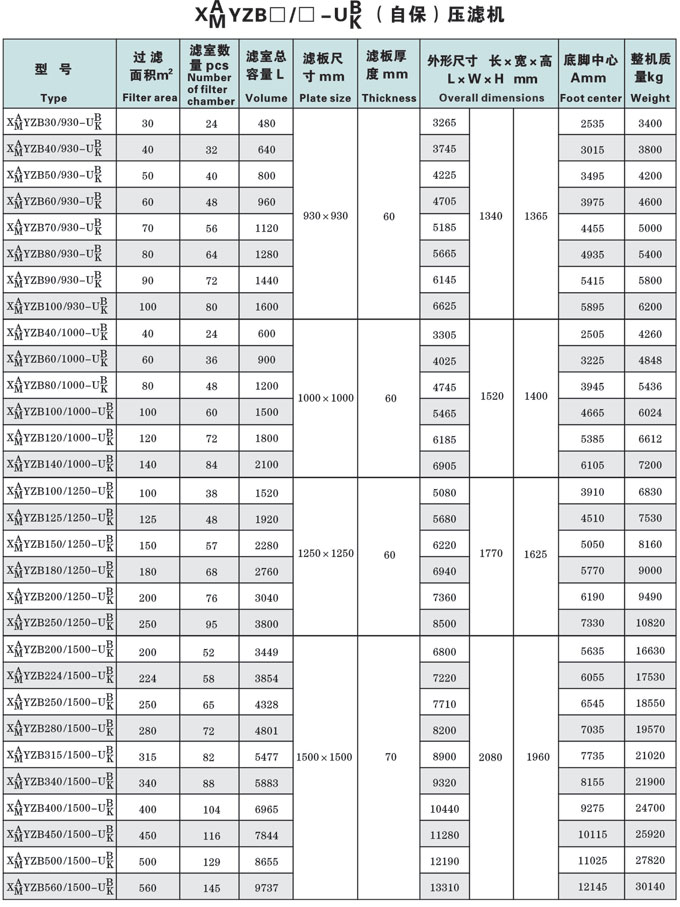

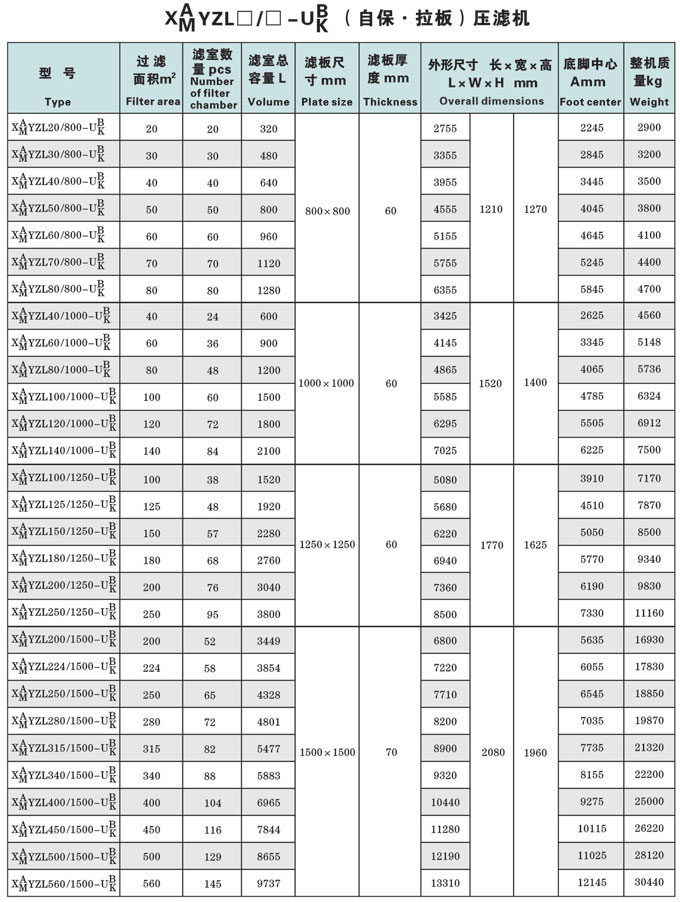

General Recessed Filter Press Models

Each type of filter press has many possible technical configurations. The charts here are for general reference only. Hengda Engineering Department designs and constructs each filter press according to project specifications.